Tel: +86 18663217757 E-mail: loonhai@loonhai.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

LH120-2400

Column palletizer, widely used in petrochemical, synthetic rubber, fertilizer, salt, building materials,

grain, food, beverage,tobacco and alcohol, steel, postal, port and other industries of granules,

powders, blocks, flakes, boxes, Packaging andpalletizing production line for solid and liquid materials

such as boxes, bottles, bags, barrels, etc.

The single-column robot palletizer can handle bags containing stable, aerated or powdery products,

permitting partial overlapping of the bags in the layer along both the top and sides, offering flexible

format changes.Its extreme simplicity makes it possible to palletize even on pallets sitting directly on

the floor.

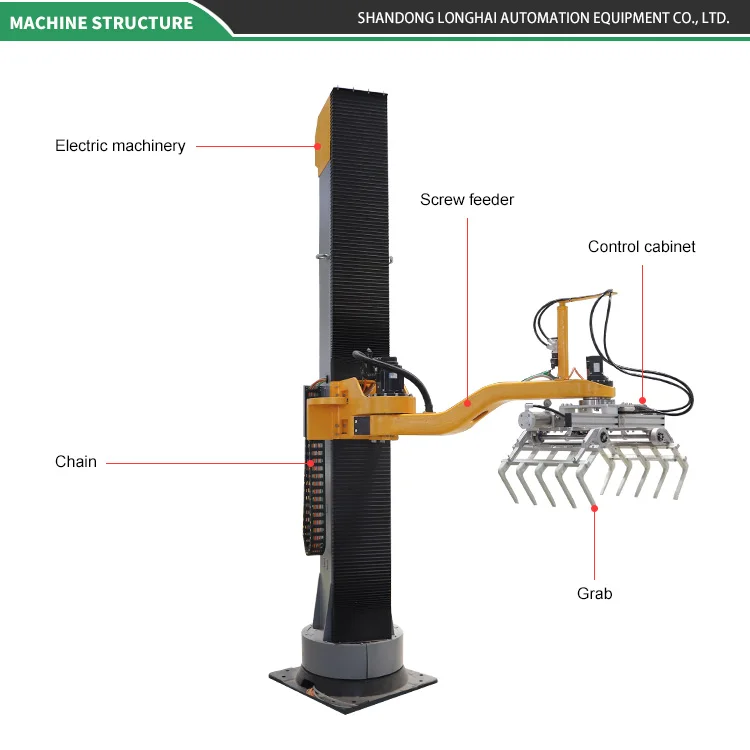

The machine features a sturdy rotating column with a rigid horizontal arm connected to it that can

slide vertically along the column. The horizontal arm has a bag pick-up pincer mounted on it that

slides along it, rotating around its vertical axis. The machine takes the bags one at a time from the

roller conveyor on which they arrive and places them at the point assigned by the program.

The horizontal arm descends to the necessary height so that the pincer can pick up the bags

from the bag infeed roller conveyor and then it ascends to permit free rotation of the main column.

Customers all over the world acknowledged our palletizers:| Model No. | LH120-2400 | Palletizing | |

| Max. load | 120 KG | parameters | 300-450 times/h |

| Maxi. activity radius | 2400-2600 mm | Number of palletizing layers | 1-10 floors |

| Control mode | Computer and controller communication control | Maxi mum stacking height | 1.8 m |

| Repeat positioning accuracy | ±0.3mm | program storage Palletizing working hours | 24h continuous operation |

| Drive mode | ervo drive | ||

| Vehicle | Fixture | ||

| Palletizing memory | Intelligent memory | ||

| Machine weight | 956kg |

The single-column robot palletizer can handle bags containing stable, aerated or powdery products, permitting partial overlapping of the bags in the layer along both the top and sides, offering flexible format changes.Its extreme simplicity makes it possible to palletize even on pallets sitting directly on the floor.

The machine features a sturdy rotating column with a rigid horizontal arm connected to it that can slide vertically along the column. The horizontal arm has a bag pick-up pincer mounted on it that slides along it, rotating around its vertical axis. The machine takes the bags one at a time from the roller conveyor on which they arrive and places them at the point assigned by the program.The horizontal arm descends to the necessary height so that the pincer can pick up the bags from the bag infeed roller conveyor and then it ascends to permit free rotation of the main column.

| Name | Size | Downloads | Update | Category | Thumbnail | Download |

|---|---|---|---|---|---|---|

| Longhai automation equipment.pdf | 5.97MB | 10 | 2025-06-06 |  | Download |